The importance of calibration recordings with TRPS

TRPS enables the characterisation (size, concentration and charge) of nanoparticles suspended in electrolyte by comparison to calibration particles of known size, concentration and surface charge. Hence good calibration recordings are of utmost importance to obtain accurate and reliable data. Izon calibration particles are charged carboxylated polystyrene particles (CPCs) for nanoparticle size, concentration and zeta analysis.

Preparation of the calibration particles before use:

The Izon calibration particle vials contain particles of a known concentration and size and are suspended in de-ionised water containing 0.05% w/v sodium azide to prevent microbial contamination. Calibration particles may settle and aggregate during transit and storage and thus before use, the concentrated particles stock must be homogeneously dispersed throughout the carrier fluid and any aggregates broken up by vortexing. All Izon calibration particles must be diluted before use and where possible, the calibration particles must be suspended in the same solution that the samples are suspended in. For more details click here.

Each nanopore size has an optimal sample dilution. If the sample is too concentrated, the nanopore may become blocked, particularly when pressure is applied. If the sample is too dilute, the particle count will be very low leading to inaccurate results.

We recommend that fresh diluted calibration solutions should be prepared each day. This will minimise the risk of significant particle aggregation, contamination or microbial growth. The re-dispersion of calibration particles should be repeated at regular intervals during the day by vortexing the sample in short bursts for 30 seconds. This is particularly important for calibration particles >500 nm in diameter as they tend to settle under gravity. Before TRPS measurements, all calibrations and samples should be vortexed briefly to ensure accurate readings.

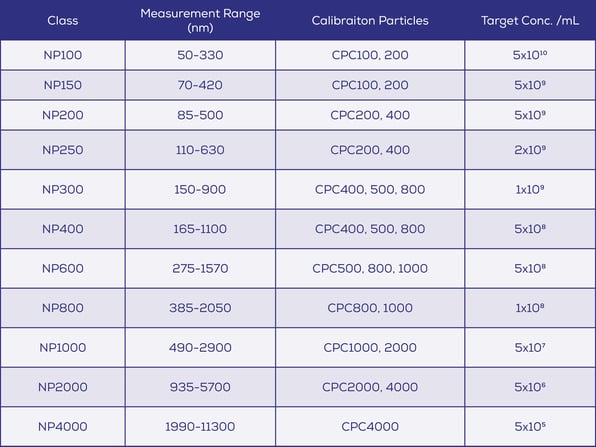

Figure 1: Guide to Izon Nanopore categories and their corresponding appropriate calibration particles sizes and target concentrations.

Measurement plan and calibration of sample measurements:

While undertaking TRPS measurements, measurement planning is crucial. It is good practice to take a calibration recording after each sample recording. Provided that the samples do not modify the nanopore, a few samples can be recorded in succession before a calibration is recorded.

For example, ideally, a sample is measured by recording a calibration particle in between each sample e.g. Cal 1 (C1), Sample 1 (S1), C2, S2, C3, S3, C4, etc... Alternatively, the samples could also be measured in this configuration: C1, S1, S2, C2, S3, S4, C3, etc. (Recommended). C1, S1, S2, S3, ......C2 is a risky configuration as some samples may modify the nanopore and cause calibration runs to be invalid.

Sample measurements need to be manually calibrated. For a step-by-step guide on calibration of sample measurements click here.

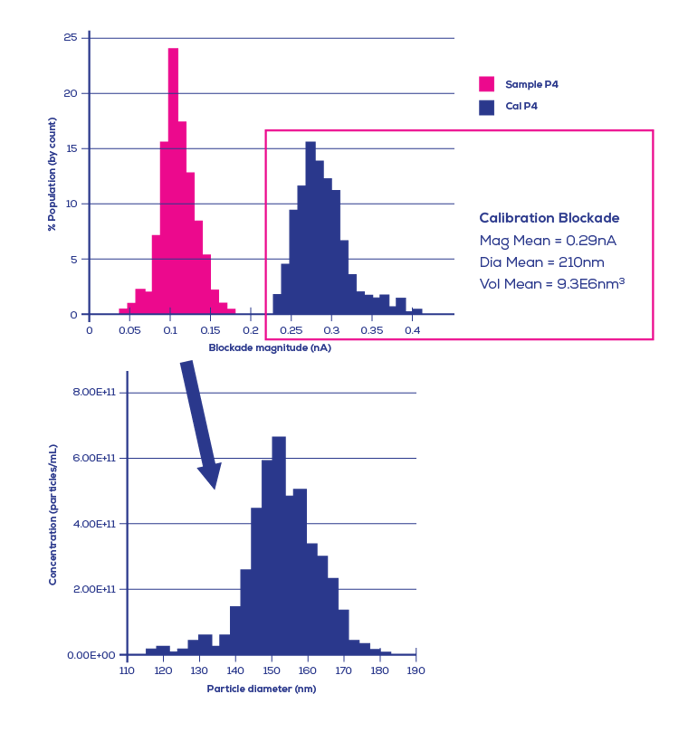

Izon Software records blockades in nA and when calibrated against calibration particles of a known size this blockade magnitude (nA) is converted into a diameter (nm) as shown in Figure 2. Blockade magnitude is proportional to the volume of the particle passing through the nanopore, giving very high resolution of particle diameter.

Figure 2: The Izon Data Suite is able to convert blockade magnitude into a particle diameter by using calibration particles of a known size.

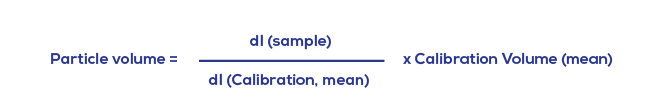

For each sample particle passing through the nanopore.

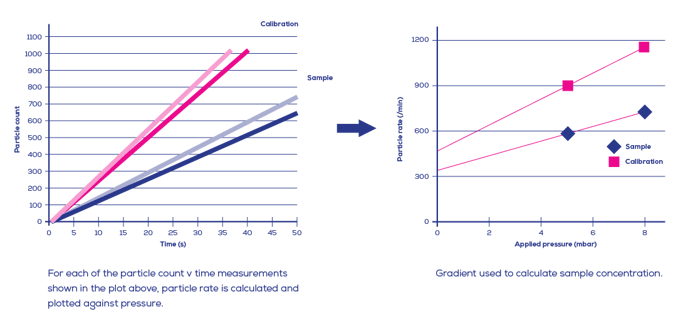

Particle concentration is proportional to the change in blockade rate per unit of applied pressure. Accurate concentration values are typically derived at 2 or more pressure steps using calibration particles of a known concentration (Figure 3).

Figure 3: Particle concentration value is measured by comparing the gradient of the rate plot of sample to calibration measurements.

The particle rate observed should increase linearly with applied pressure and is indicative of system stability.

For accurate and precise results, the sample and calibration particles must be recorded under identical system settings, which includes the electrolyte characteristics, which affect the baseline current and blockade magnitude. When possible, always use the same electrolyte. Adjusting any of the parameters between the sample and calibration recordings will affect blockade magnitude and particle rate, invalidating the sample-calibration pairing. Sample and calibration particles should be recorded at the same time – one immediately after the other, or as close together as possible if the system is stable enough to record 2-3 samples before the system needs to be recalibrated.