Nanopore characterisation and set-up overview

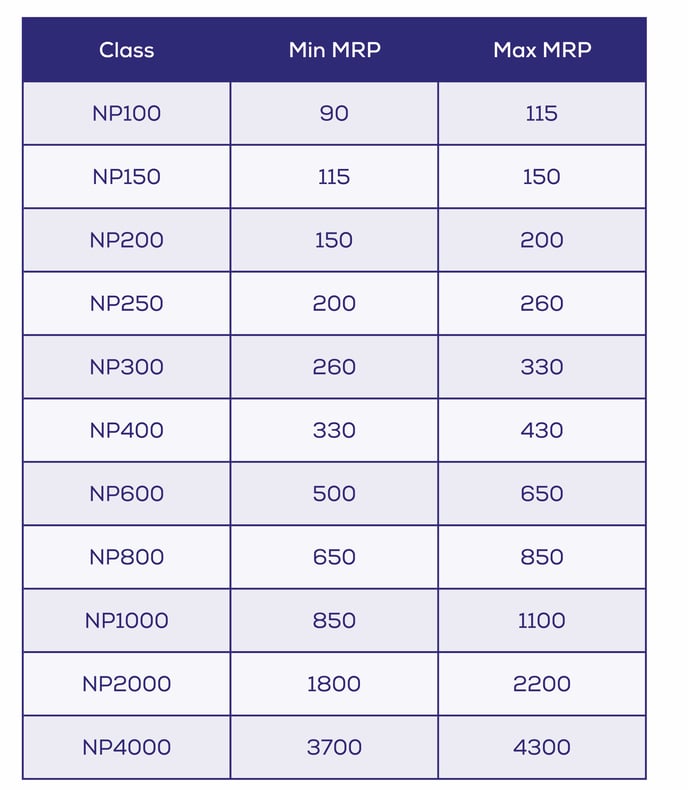

At production, a calibration particle of a known size is measured on a known stretch and a known pressure through an unknown sized hole to determine its size. The size of the blockade produced has a direct relationship with the size of the hole. MRP (Mid-Range-Particle) is the measure used by Izon to classify nanopores in terms of their size. MRP is defined as the particle diameter which produces a blockade magnitude or ΔI = 0.3 nA, relative to a baseline current of 100 nA (ΔI/I = 0.003) at a stretch of 47 mm and 10 mbar applied pressure. Utilising this knowledge, the MRP of each individual nanopore is calculated and a size is assigned to the nanopore. Each nanopore category has an acceptable MRP range which allows for the resolution of the particle sizes recommended. For example, an NP100 would have an MRP value between 90-115 nm. Each pore is characterised by measuring the MRP before being released for sale.

At the hands of the user nanopore set-up involves two steps: Wetting and Coating. Wetting is essential for all nanopores. Our nanopores are made of a hydrophobic polymer called thermoplastic polyurethane (TPU). During wetting, the Izon Wetting Concentrate facilitates establishing a fluid flow between the upper and lower fluid cells in the qNano system. Proper wetting of the hydrophobic nanopore is essential to achieve stable baseline currents on application of a voltage. For further information please click here.

Coating nanopores is recommended for all samples, however it is compulsory when using biological samples. Coating minimises non-specific binding (NSB) of particles to the TPU and increases running capabilities of the nanopore. NSB can interfere with TRPS measurements in two ways – firstly, contaminating molecules can bind to the nanopore, altering its size and conductance properties, and secondly, samples such as extracellular vesicles (EVs) themselves can bind to the membrane, causing it to block and preventing further measurements. Coating the nanopore therefore increases the stability of TRPS measurements when using samples of a biological nature. Izon Coating Solution (ICS), is a protein-free PBS-based formulation, which is used to coat the TPU nanopores before measuring particles especially from biological fluids. For further information please click here.