When and how should I clean the lower fluid cell?

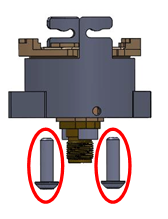

Excess fluid can sometimes get in the lower fluid cell between the metal and plastic material. This can be caused by excessive clicking of the fluid cell cap or excessive washing of the lower fluid cell. Presence of stray fluid in the lower fluid cell can cause a temporary short circuit and if not treated quickly, rusting of the metal parts.

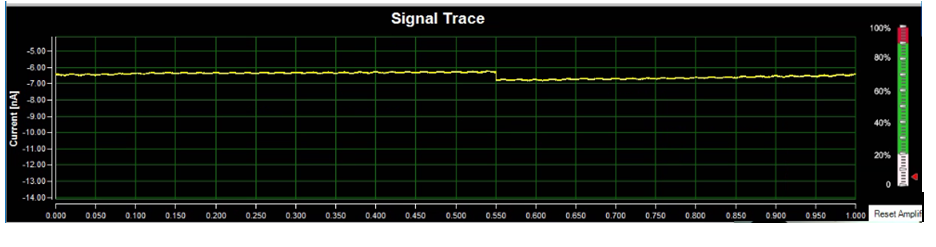

The system could have a short circuit if the baseline current goes to a negative value (nA) such as the example below:

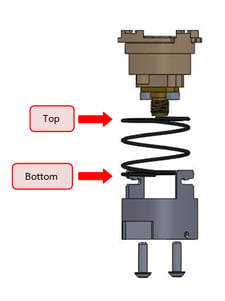

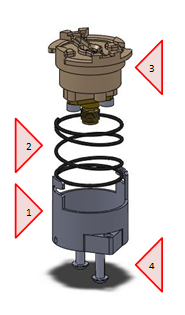

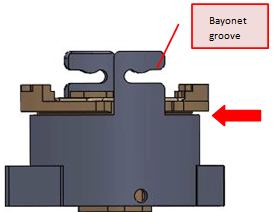

When this happens, the lower fluid cell should be taken out and thoroughly cleaned. Take extra care to not drop or knock the fluid cell as the arms of it can bend and break off.

Cleaning of fluid cell