Overview: Measurement of particles on larger nanpores (NP1000 and larger)

Using a TRPS system to analyse microparticles (NP1000 nanopores and larger) requires a slight change in both sample preparation and measurement protocols.

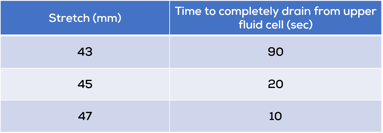

Fluid can flow through large pores very quickly. Even if no pressure is applied, gravity can cause the sample fluid to “drain” from the top to the bottom of the NP4000 pores in a matter of minutes. This causes the following issues:

- The effective pressure head of the system changes as the fluid drains from the top to the bottom. This manifests itself as a drop in fluid flow rate (therefore particle count rate) over time. The rising meniscus in the lower fluid cell can even push fluid back up through the pore into the upper fluid cell when the pressure is no longer applied.

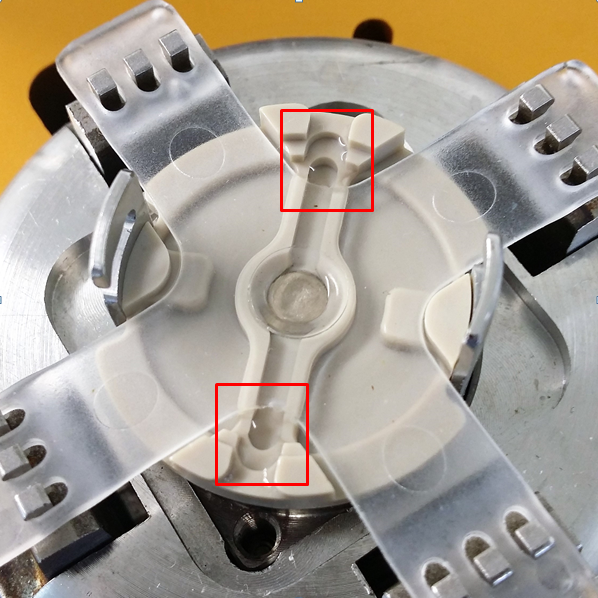

- As the fluid drains into the lower fluid cell, it fills up the feed channels. This fluid can then overflow from the channel at each end, causing a short circuit between the signal electrode in the cell (where the voltage is applied) and the earthing path in the stainless steel shell. This can cause “railing” of the electronics.

If the system continues to "rail" it is recommended to dilute the buffer being used. For example if PBS electrolyte is used, the conductivity should be made to 20% or 10% strength by diluting the electrolyte with deionised water.

Due to these effects the flow rate is likely to change significantly over the course of a measurement. This will manifest itself both in the blockade rate and the blockade shape.

Related Articles: